Current Status of Environmental Remediation Sites

The good news is most have been remediated and are now being monitored to assure the remediation work has been successfully completed

Area of Concern

OMC Plant and adjacent sites

The following status summary is provided by the US Environmental Protection Agency (EPA) Superfund website (See the complete EPA summary)

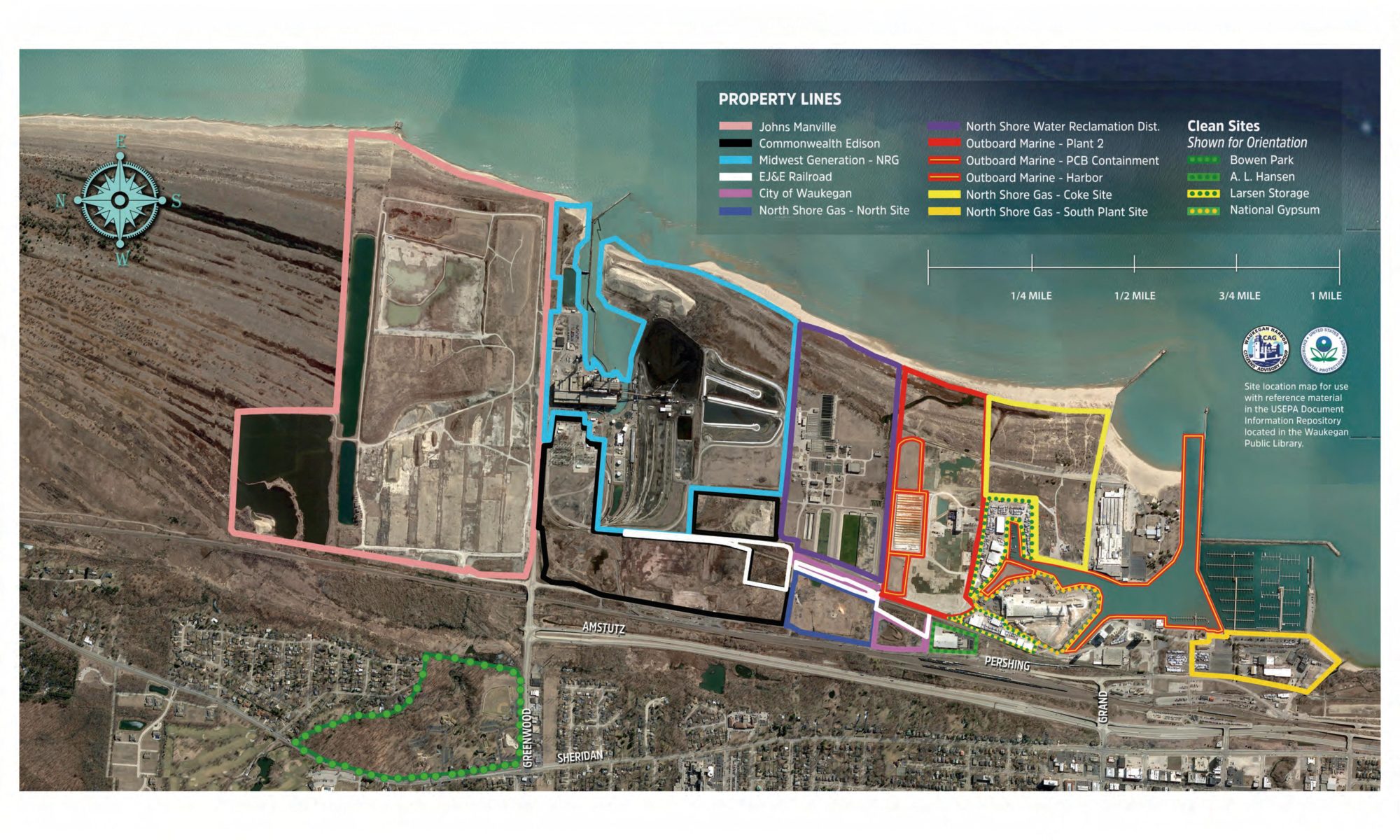

History: The Outboard Marine Corporation (OMC) site is located in the northern section of Waukegan Harbor in Waukegan, Illinois. The 100-acre area along the shore of Lake Michigan is the former location of an outboard-boat-motor manufacturing plant and a former railroad tie, coal gasification and coke plant facility. Contaminants of concern include polychlorinated biphenyls (PCBs), which OMC used in hydraulic fluids at its boat motor manufacturing plant, and trichloroethene (TCE), a chlorinated solvent that OMC used to degrease newly made parts. Following immediate actions to protect human health and the environment, the site’s long-term cleanup is ongoing.

Status: EPA divided the site into four areas for cleanup. The status of each area is discussed below.

Waukegan Harbor: OMC, under EPA oversight, first cleaned up Waukegan Harbor in 1992 by dredging PCB-contaminated sediment. To fully clean up the harbor, from 2012-2013 EPA hydraulically dredged harbor sediment with residual PCB contamination and consolidated it on site. During 2014, the dredging-related equipment was removed and the consolidation facility was capped. The State of Illinois will continue to monitor PCB levels in harbor fish annually. (Also see Harbor History)

Former Waukegan Manufactured Gas and Coke Plant (WCP): Soil cleanup began in November 2004 and finished in November 2005. Thousands of tons of contaminated soil were dug up and removed. Once cleanup levels were met, excavated areas were backfilled with clean material, and a clean top soil layer placed over the site. The City of Waukegan owns and maintains the property. Groundwater cleanup consists of two phases, one active and one passive. The active phase began in the fall of 2008 with construction of a groundwater treatment plant. Treatment took place in innovative aerobic (oxygen-loving) bacterial reactors in which the organic chemical contaminants served as food for the bacteria. “Digested” water was then filtered and pumped back into the ground. Active groundwater cleanup finished in September 2011. All machinery has since been dismantled. The passive phase began in early 2012. This phase includes monitoring remaining residual groundwater contamination until cleanup goals are met. In 2015, the U.S. Army Corps of Engineers placed clean sediment dredged from the outer section of Waukegan Harbor onto the Waukegan Coke Plant site under an agreement between EPA, Illinois EPA, and the City of Waukegan. The sediment will be part of a city-planned 3 foot-thick clean soil barrier to permit residential development of the property.

PCB Containment Cells: Three PCB containment cells were put in and filled in 1992. The City of Waukegan, under EPA oversight, is in charge of their operation and maintenance. Since 2005, the city has maintained surface covers on the containment cells, conducted routine inspections and operated groundwater pumps to remove and treat water from inside the cells. To date, monitoring shows that the cells are robust and no leaks have occurred. In 2014-15, a new containment cell was completed to encapsulate very contaminated soil discovered in the southwestern portion of the site.

OMC Plant 2: EPA received funding under the American Recovery and Reinvestment Act (ARRA) in June 2009 to begin cleanup work on the PCB-contaminated Plant 2 building. Demolition work on the 600,000-square-foot building began in January 2010 and finished in July 2010. About 5,000 tons of steel were recovered, most of which was recycled locally. In 2010, EPA also began digging up and removing contaminated soil and sediment for off-site disposal. Excavation and off-site disposal of over 350,000 cubic yards of soil and sediment was substantially completed in 2015. A groundwater plume highly contaminated with site-related solvents (referred to as dense non-aqueous phase liquids, or DNAPLs) was treated in 2011 with bentonite clay and zero-valent iron to break down the contaminants. Other lower concentration contaminated groundwater plumes were treated in 2014 by injecting the groundwater with an oxidizer (sodium permanganate) to break down the solvents. To address groundwater contamination near the property’s south boundary, an air sparging system was installed in September 2011. Groundwater treatment is nearing completion and will be followed by monitoring remaining residual groundwater contamination until cleanup goals are met.

North Shore Gas South Plant

The following status summary is provided by US Environmental Protection Agency (EPA) Superfund website (See the complete EPA summary)

History: The North Shore Gas (NSG) South Plant former Manufactured Gas Plant (MGP) site is located on Pershing Road in an industrial / commercial area of Waukegan, Illinois. The site, which covers over 20 acres, includes the 1.9-acre former MGP facility along Pershing Road and adjacent areas where MGP residuals have been found. They include:

- Waukegan Port District (WPD) – located east of the former MGP. This area includes a marina, a visitor center / administration building, a maintenance building, and parking lots. It is 13.1 acres and is adjacent to Lake Michigan.

- Akzo Nobel Aerospace Coatings, Inc. (Akzo) – located east / southeast of the former MGP and adjacent to Lake Michigan. The property is approximately 6.2 acres and consists of buildings and parking lots.

- Elgin, Joliet and Eastern (EJ&E) – refers to the railroad tracks and right-of-way (ROW) located east and at the south end of the former MGP. This parcel is approximately 0.7 acres.

- City of Waukegan (COW) – located southeast of the former MGP between the EJ&E, Akzo, and WPD properties. This property is a vegetated and vacated former city street ROW. This parcel is approximately 0.5 acre. Other COW property investigated includes nearby roads and associated ROWs.

MGPs were industrial facilities that produced gas from coal, oil and other feedstocks. The site is not listed on the National Priorities List (NPL) but is considered to be an NPL-caliber site and is being addressed through the Superfund Alternative Approach.

Status: The site is currently in the Remedial Design / Remedial Action stage of the Superfund Process.

U.S. Environmental Protection Agency issued the Final Remedial Design Report PDF(823pp, 55.87MB, About PDF) in 2019 for the interim remedy selected for an area of undissolved tar-like liquids beneath the former North Shore Gas South Manufactured Gas Plant. The remedy is documented in the July 2015 Record of Decision for Interim Action (ROD)(PDF)(56pp, 13.29MB, About PDF).

With the completion of the design report North Shore Gas is set to begin implementing cleanup actions to recover the tarry substance, which is called dense non-aqueous phase liquid, or DNAPL, using a network of groundwater injection and extraction wells. DNAPL is the primary source of groundwater contamination at the site. “Groundwater” is an environmental term for underground supplies of fresh water. This is an interim cleanup action to specifically tackle the DNAPL. A final cleanup plan to manage other soil and groundwater contamination will be issued after these cleanup steps are completed.

Groundwater and DNAPL extracted from the system will be pumped as separated fluids to a groundwater treatment plant, where DNAPL will be directly pumped into a DNAPL storage tank and the groundwater will undergo treatment. The separated DNAPL will be packed and shipped off-site for disposal. Extracted groundwater will be treated on site and reinjected into the aquifer, which is expected to help move the DNAPL towards the recovery wells.

With the completion of the design report North Shore Gas is proceeding to implement cleanup actions to recover the tarry substance, which is called dense non-aqueous phase liquid, or DNAPL, using a network of groundwater injection and extraction wells. DNAPL is the primary source of groundwater contamination at the site. “Groundwater” is an environmental term for underground supplies of fresh water. This is an interim cleanup action to specifically tackle the DNAPL. A final cleanup plan to manage other soil and groundwater contamination on the site will be issued after DNAPL remediation has been completed – estimated to be up to 8 years from start of cleanup.

Extended Area of Concern

Johns-Manville

The following status summary is provided by US Environmental Protection Agency (EPA) Superfund website (See the complete EPA summary)

History: The Johns-Manville site is a 150-acre asbestos disposal area in Waukegan, Illinois. About 3 million cubic yards of off-specification products and wastewater sludge were disposed of at the site. Johns-Manville ceased operations on site in the summer of 1998. All former manufacturing buildings were demolished in 2000-2001. Asbestos is the primary contaminant of concern. Following an extensive cleanup, sampling identified seven additional areas of asbestos contamination outside of the Johns-Manville fence line. Cleanup of these areas as well as groundwater monitoring are ongoing.

Status:

EPA’s cleanup of this site consisted of consolidating waste into the Industrial Canal, Pumping Lagoon, and Black Ditch areas and placing clean soil with vegetation over the waste disposal areas; placing sand and gravel on all site roadways; institutional controls; and periodic sampling of air, soil cover and groundwater to ensure the cleanup continues to protect people and the environment. For the complete response action summary at the site, see Section II of the Fifth Five-Year Review Report (PDF) – 2018 (50 pp, 10.16 MB).

JM Waste Disposal Area (OU1) :Construction activities are complete within OU1. The on-site landfill, wastewater treatment area, manufacturing areas, perimeter roads, and related areas have been excavated and/or capped with rock or a vegetated cover as required, with completion occurring in 2017. A stormwater drainage system intercepting clean stormwater runoff and discharging to Lake Michigan was installed and operational in 2017. EPA conducted site closure inspections in 2018, and JM provided two reports: Revision 1 of the Final Closure Report, Non-Asbestos-Containing On-Site Landfill (PDF)(1035pp, 50.34MB, About PDF) and the Final Closure Report for the Former Industrial Canal, Pumping Lagoon & Collection Basin, Revision 1 (PDF) (7059 pp, 479.83MB, About PDF).

Continued monitoring and maintenance as part of the operation and maintenance plan, particularly within the Settling Basin, are necessary as vegetation establishes.

Shooting Range (OU2): Construction activities are complete within OU2. Asbestos impacted materials were removed from the upper two to three feet of the site in 2002 based on targeted sampling results. Additional asbestos material was discovered in subsurface soils during monitoring well installation, however the material was determined to be contained by the installed cover and no additional removal was necessary.

Parking Lot (OU3): Construction activities are complete within OU3. The site was partially excavated and a clean cover / clean-soil corridor for utilities was installed in 2016. Vegetation was established by 2017. Closure reports are being developed for the southwestern area sites (OU3, 4, and 8) and closure inspection will be held in 2018.

Site 4/5 (OU4): Construction activities are complete within OU4. Soils with detectable concentrations or visually identified asbestos-containing material (ACM) were removed from the site, clean fill was placed, and the wetland areas were mitigated. Vegetation of the site occurred in 2016. Closure reports are being developed for the southwestern area sites (OU3, 4, and 8) and closure inspection will be held in 2018.

Nature Preserve Road (OU6):The United States Army Corps of Engineers has prepared a draft Feasibility Study to cleanup residual contamination in OU6 (Site 1) also known as the Nature Preserve Road. No remedy has been selected yet. U.S. EPA has been coordinating with the Illinois EPA, Illinois Department of Natural Resources, Illinois Nature Preserves Commission, and the USACE in the development of a remedy for OU6. ACM remains in subsurface soils and may appear at the surface periodically due to freeze-thaw migration or erosion. In coordination with IDNR, contractors have occasionally picked up surficial ACM and disposed of the waste.

Greenwood Avenue Shoulder (OU8): Construction activities are complete at OU8. Material was excavated from the site and placed in the on-site consolidation area, and a clean sand cover was completed in 2017. Closure reports are being developed for the southwestern area sites (OU3, 4, and 8) and closure inspection will be held in 2018.

North Shore Gas North Plant

The following status summary is provided by US Environmental Protection Agency (EPA) Superfund website (See the complete EPA summary)

History: The 16-acre North Shore Gas North Plant former Manufactured Gas Plant (MGP) site is located in Waukegan, Illinois, at the intersection of Pershing and Dahringer Roads. The site has been contaminated with MGP residuals from historical plant operations. Previous EPA actions in the 1990s and in 2013 addressed the most egregious sources of contamination. Site investigation and ground water monitoring are ongoing to characterize the remaining contamination at the site. The site is not listed on the National Priorities List (NPL) but is considered to be an NPL-caliber site and is being addressed through the Superfund Alternative Approach.

Status: North Shore Gas is completing an investigation of the site contamination under the 2007 EPA order (82 pp, 6.72 MB). The investigation is being conducted in accordance with EPA’s Superfund cleanup process, using an approved work plan (146 pp, 182.93 MB) under the 2007 EPA order. The work is expected to be completed in 2018, with the results described in a remedial investigation (RI) report that will be submitted to EPA for review and approval in late 2018 or 2019. Following submittal of the RI report, a feasibility study (FS) describing the various cleanup plans to address unacceptable risks posed by remaining site contaminants, if there are any, will be submitted to EPA for review and approval. Following approvals of the RI and FS reports, EPA will propose its preferred cleanup plan for public comment. Based on responses it receives during the comment period on its proposed plan, EPA will issue a decision on final cleanup plan.

Yeoman Creek Landfill

The following status summary is provided by US Environmental Protection Agency (EPA) Superfund website (See the complete EPA summary)

History : The 70-acre Yeoman Creek Landfill site is located in Waukegan, Illinois. A landfill operated on site from 1959 to 1969. The landfill has no bottom liner and the underlying soils are permeable. Polluted liquid from the landfill contains chemicals, elevated concentrations of metals and ammonia. Landfill gas was detected migrating off site. The site’s long-term remedy is in place. Study of landfill gas migration and groundwater monitoring are ongoing.

EPA is the lead agency in partnership with Illinois EPA overseeing the potentially responsible parties’ (PRPs’) cleanup of the site.

EPA has conducted several five-year reviews of the remedy. These reviews ensure that the remedies put in place protect public health and the environment, and function as intended by site decision documents. Most issues identified during the 2007 five-year review have been addressed. The PRPs completed construction of a new perimeter trench gas collection system as well as drainage system improvements, grading and seeding in 2009. However, landfill gas on the northern portion adjacent to the site continues to be a problem and is being studied. Groundwater monitoring is ongoing.

Status: The site is being addressed in two stages: immediate actions and a long-term phase focused on cleanup of the entire site. In 1980, the city upgraded the site cover in most areas of the landfill. The site’s potentially responsible parties fenced the site in 1990 and installed a ventilation system in a building next to the site in 1994. EPA selected the site’s long-term remedy in 1996. It included sediment collection in Yeoman Creek and limited wetland areas, reconstruction of Yeoman Creek, a flexible landfill cover, continuation of measures to address landfill gas, waste consolidation and extensive long-term monitoring. Remedy construction took place from 2002 to 2005.

Activity and Use Limitations: At this site, activity and use limitations that EPA calls institutional controls are in place. Institutional controls play an important role in site remedies because they reduce exposure to contamination by limiting land or resource use. They also guide human behavior. For instance, zoning restrictions prevent land uses – such as residential uses – that are not consistent with the level of cleanup.

For more background, see Institutional Controls.

Contaminants of concern at the site include volatile organic compounds (VOC), polychlorinated biphenyls (PCB), bis(2-ethylhexyl)phthalate, and elevated concentrations of lead, manganese, iron, chloride, and ammonia.